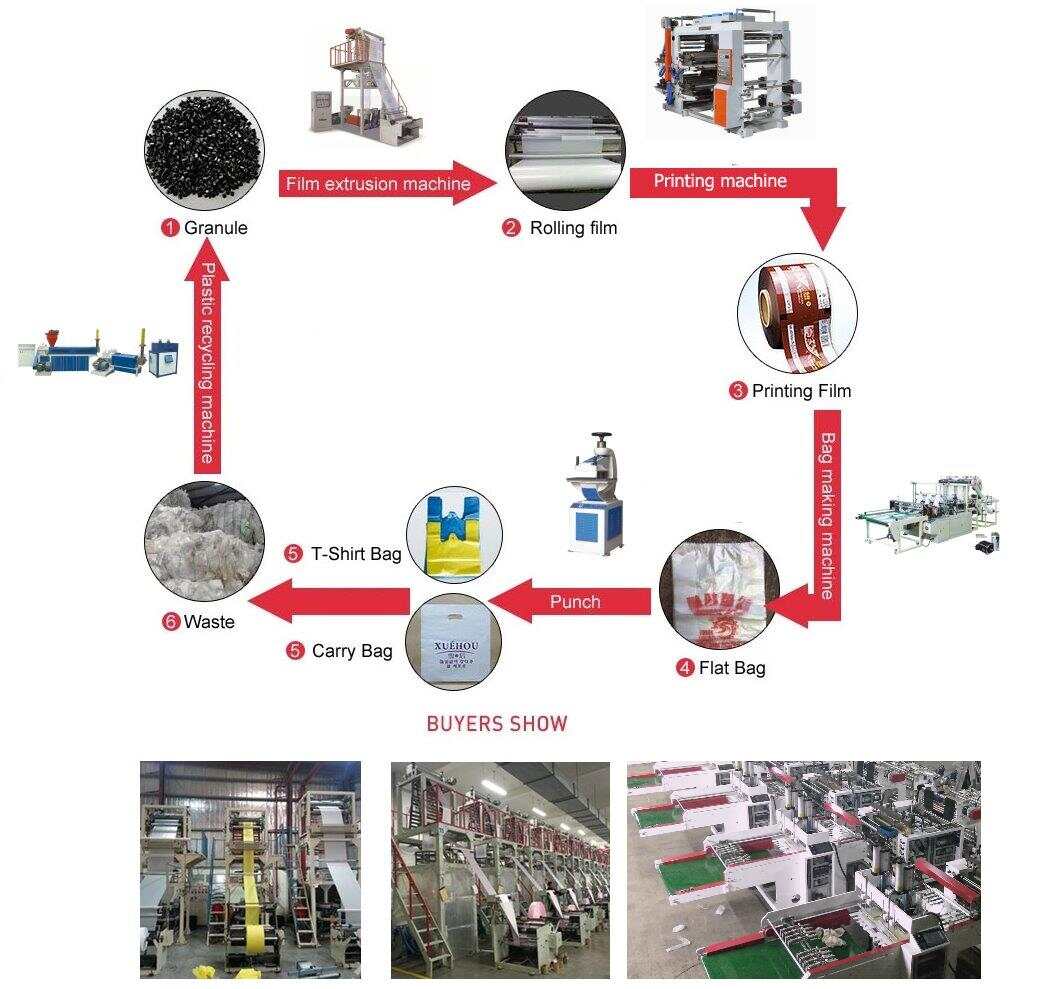

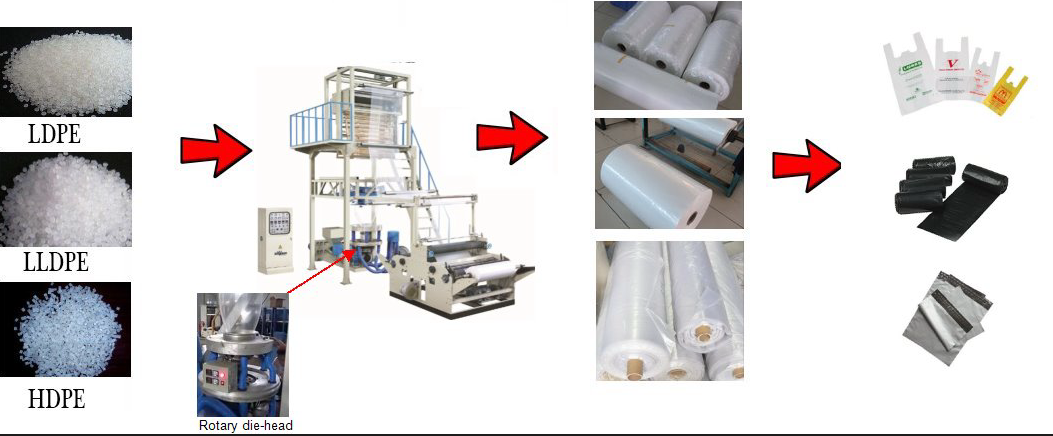

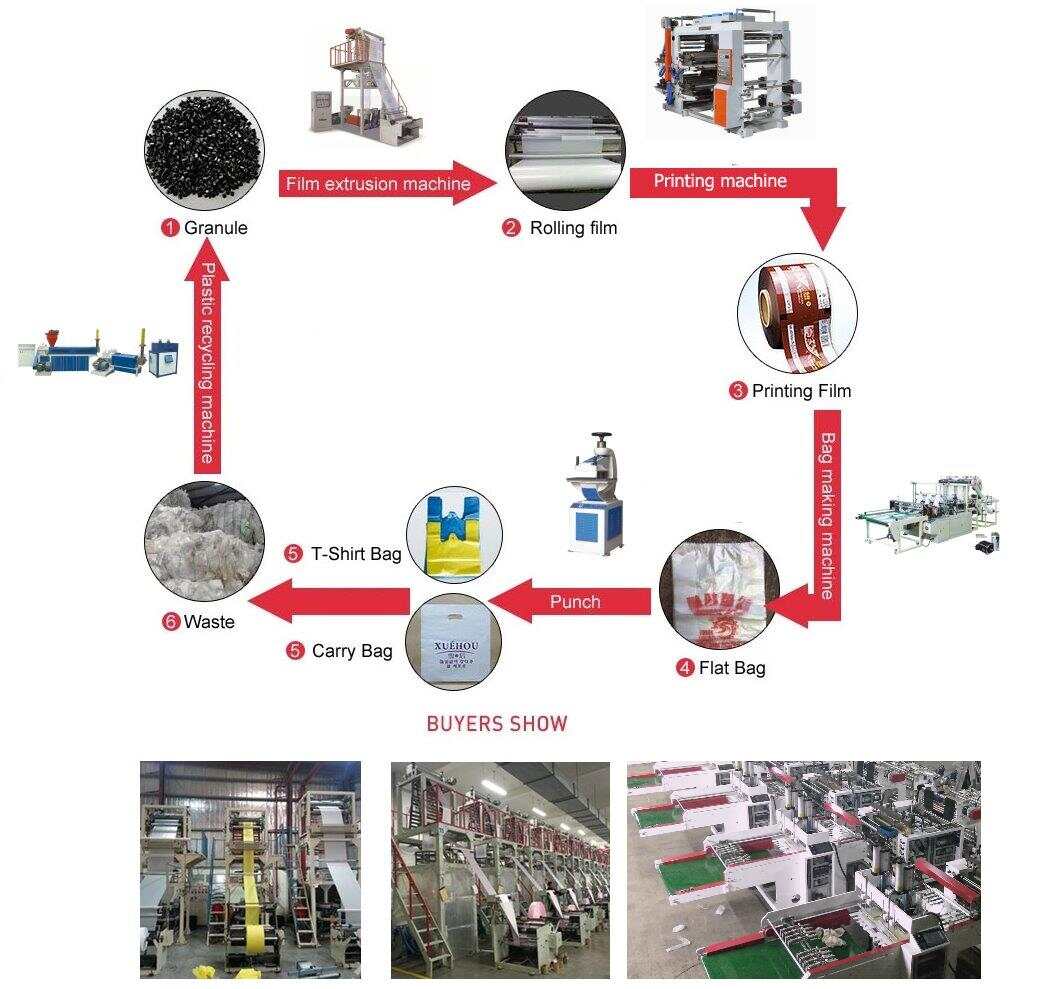

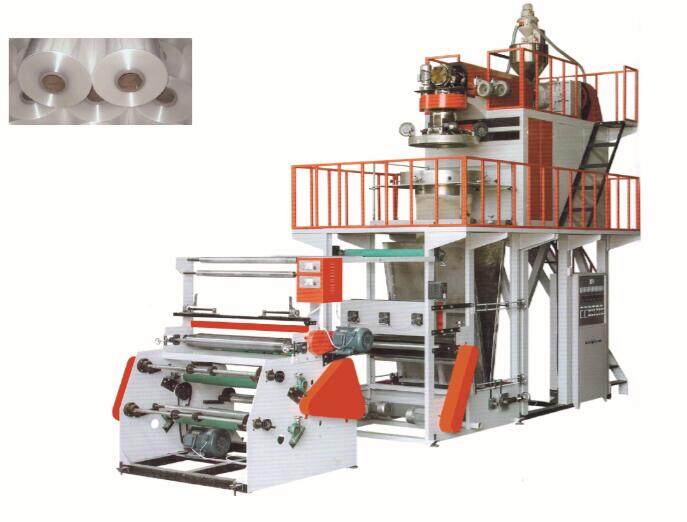

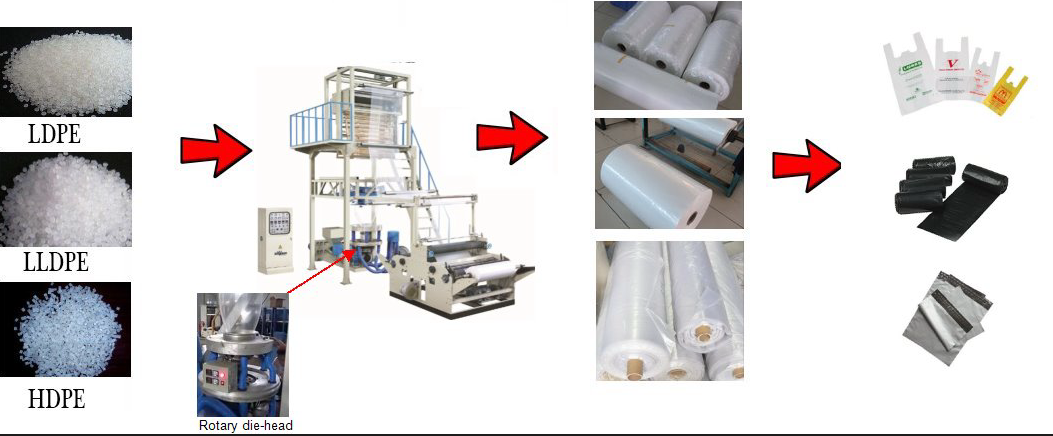

Rotary Die-head Film Blowing Machine is the plastic film blowing machine for blowing PE(HDPE, LDPE, LLDPE), film; etc.

This machine with extruder,cylinder and screw rods of machine are made of quality alloy steel that have been nitrized and processed in a precision way. So it is in hardness, durable in corrosion resistance. The specially-designed screw is of sound quality in plasticizing, which helps increase the production capacity. It is applied to blowing the plastic films like low density polyethylene (LDPE), high density polyethylene (HDPE). It is widely applied to producing the packing bags for foodstuff, clothing, rubbish bag and vest ones.

CHARACTERISTIC

1. Frequency inverters control main motor and traction motor.

2. Material of screw and barrel: 38CrMoAl after nitrogen treatment

3. Gear box: HARD teeth gear surface, casting alloy piston, high precise grinding.

4. Die material: ALLOY mold steel No.45 material, hard chrome- plating

5. Double digital display temperature controller in the die head.

Optional Equipments:

1)Auto Loader

2)Air Compressor

3)Up and Down

4)Air Shaft

5)Masterbatch Dosing device

6)Automatic Winder Changer

7) Corona treatment

|

Model

|

SJ-B50

|

SJ-B55

|

SJ-B60

|

SJ-B65-1

|

|

Material

|

LDPE, LLDPE,HDPE,virgin raw material, recycled material,

CaCO3 compound,masterbatch and additives material

|

|

Film Color

|

Transparent,Black,Red,White,blue…bag color changed by Masterbatch

|

|

Usage

|

Flexible packaging bags,T-shirt bag,Plastic Shopping Bag,trash bag,packing film,table cover,shrink film

|

|

Diameter of screw

|

φ50

|

φ55

|

φ60

|

φ65

|

|

Reduced diameter of film

|

100-600 mm

|

200-800 mm

|

300-1000 mm

|

400-1200 mm

|

|

One side film Thickness

|

0.01-0.10 mm

|

|

Max.capacity (Kg/h)

|

35

|

50

|

65

|

80

|

|

Ratio of Screw L/D

|

28:1

|

28:1

|

28:1

|

28:1

|

|

Screw material

|

38CrMoAl

|

38CrMoAl

|

38CrMoAl

|

38CrMoAl

|

|

Power of main motor(kw)

|

7.5-11

|

11-15

|

18.5-22

|

22

|

|

Power of Traction

|

1.1 kw

|

1.1 kw

|

1.5 kw

|

1.5 kw

|

|

Heating Power(kw)

|

11

|

13

|

19

|

21

|

|

Delivery Day

|

30-45 days

|

30-45 days

|

30-45 days

|

30-45 days

|

|

Machine size (m)

|

4.8x1.9x3.8

|

5.5x2.1x4.6

|

6.5x2.3x5.2

|

6.5x2.5x5.2

|

|

Weight(T)

|

1.5T

|

2T

|

2.3T

|

2.6T

|

|

Power Voltage

|

220V,380V,440V,480V(Customized based on request,For example: USA 480V 60Hz, Mexico 440V/220V 60Hz, Saudi Arabia 380V 60Hz, Nigeria 415V 50Hz...)

|

|

Material Core Diameter

|

76mm(3 inch)

|

|

Machine Working Time

|

24 hours * 7 days

|

|

Warranty

|

1 year

|

|

Optional Devices

|

Auto loader, masterbatch dosing system, rotary die head, bubble controller, corona treater, embossing roller, automatic winder, double winder

|

|

Technical Assistance

|

Engineers available to service machinery overseas

|

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

Install machines in Saudi Arabia.

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

Our Main parts cooperator as following brand,but standard parts all made from China.

How To Find Polyethelene For Blown Film Extrusion.

Extrusion Film Extrusion use Polyethelene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company